A heavy parcel arrived at work for me today, 60 ish kg apparently.

In a wooden crate, and wrapped in grease paper

So after unwrapping this is what I found, a NOS standard Sprint block - late model too, with the enlarged water pump to jacket waterway and no jackshaft wear present or damaged threads

and as my new pistons don't fit !

its off to Chesman Engineering later this week for a bore and hone

That's part 1 of the new engine underway

Tuesday, 17 November 2015

Sunday, 3 May 2015

Sprint and TR5 Work

I had been meaning to lift the rear suspension on the Sprint, via the adjustable spring seat platforms on the dampers since the RBRR.

While on that little jaunt, the ocassional bottoming out of the rear suspension had been put down to 2 fat bastards - Andy and Myself and a boot full of spares, but on the HCR I had the same issue with Anne as a co-driver - and I daren't say that she is overweight.

Looking at the car, even with no passengers the car sat lower than it should, so the tail down attitude must have been due to the rear springs settling, so this weekend I got the C spanner out and adjusted the platforms. With the seats at their highest setting, I gained another 1" of height - if I still have a problem I think new springs of a better quality will be required, but it now looks like this will be fine when driven.

I have also taken the time to fit some sound deadening material under the bonnet - it makes the engine much quieter, and the bonnet now shuts with a "thud" instead of a "clang" - This stuff is made by dynamat, and is foil ontop of a 10mm layer of foam

Back to the 5 and I finally got the fuel pipes finished and clipped into place.

I nearly forgot the tank vent

Wiring next !

While on that little jaunt, the ocassional bottoming out of the rear suspension had been put down to 2 fat bastards - Andy and Myself and a boot full of spares, but on the HCR I had the same issue with Anne as a co-driver - and I daren't say that she is overweight.

Looking at the car, even with no passengers the car sat lower than it should, so the tail down attitude must have been due to the rear springs settling, so this weekend I got the C spanner out and adjusted the platforms. With the seats at their highest setting, I gained another 1" of height - if I still have a problem I think new springs of a better quality will be required, but it now looks like this will be fine when driven.

I have also taken the time to fit some sound deadening material under the bonnet - it makes the engine much quieter, and the bonnet now shuts with a "thud" instead of a "clang" - This stuff is made by dynamat, and is foil ontop of a 10mm layer of foam

Back to the 5 and I finally got the fuel pipes finished and clipped into place.

I nearly forgot the tank vent

Wiring next !

Saturday, 25 April 2015

TR5 EFI

Today was the day to get on with the EFI system

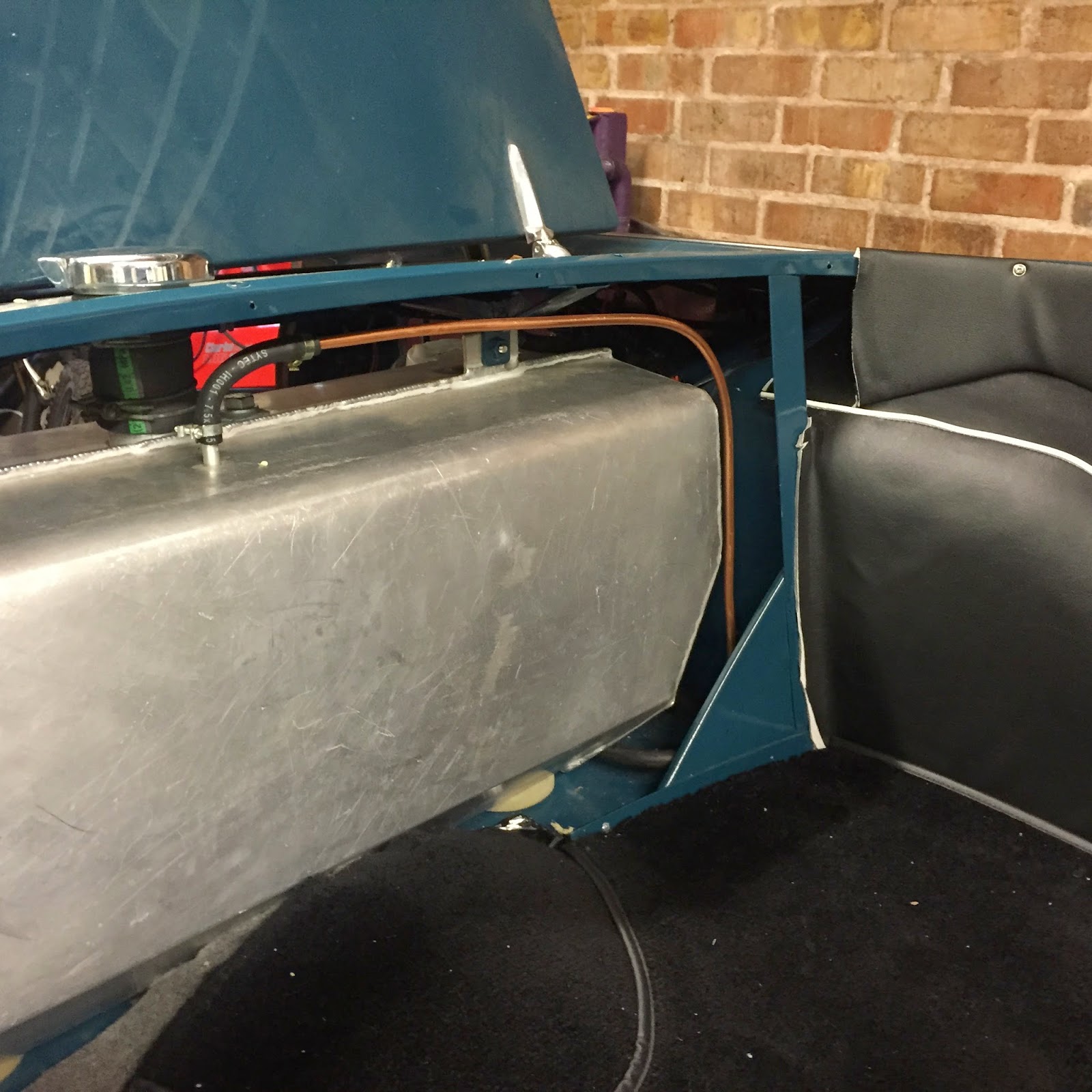

I needed to fit a lift pump to feed the swirl pot, which I fitted in the rear inner wing. This is made by webcon, and has an integral high pressure pump

The lift pump, which will "suck" was fitted to a bracket that I made and fits in snugly under the fueltank. this mounts to two existing bolt holes on a bracket, the swirl pot was fitted via rivnuts. The lift pump has a coarse filter on its input.

The same bracket holds the high pressure filter, fitted after the efi pump

The lift pump feeds the bottom of the swirl pot, and the restricted return goes back into the top of the fuel tank

Feed to the lift pump

I then fitted the high pressure fuel regulator, with a copper pipe return to the back of the engine

I had contemplated bring the fuel lines up on the manifold side of the car - normally they run to the other, distributor side as thats where the mechanical fuel injection sits, but in the end I decided to keep to the normal fuel pipe routing, and ran two rubber hoses from the manifold fuel send and return, round the back of the engine, to the normal fuel pipe positions.

I have just about finished fitting the send and return pipes down the chassis, but I need 2 grommets to pass the fuel pipe through the floor under the fuel tank, and without these I couldn't complete the work. Once these are fitted I'll finish clipping the fuel pipe to the chassis rails, and complete the job.

Before anyone asks I have flared the ends of the copper pipe so that a good reliable seal is made to the rubber.

I need to wire up the pumps, but thats a job for when I finish the wiring

I needed to fit a lift pump to feed the swirl pot, which I fitted in the rear inner wing. This is made by webcon, and has an integral high pressure pump

The lift pump, which will "suck" was fitted to a bracket that I made and fits in snugly under the fueltank. this mounts to two existing bolt holes on a bracket, the swirl pot was fitted via rivnuts. The lift pump has a coarse filter on its input.

The same bracket holds the high pressure filter, fitted after the efi pump

The lift pump feeds the bottom of the swirl pot, and the restricted return goes back into the top of the fuel tank

Feed to the lift pump

I then fitted the high pressure fuel regulator, with a copper pipe return to the back of the engine

I had contemplated bring the fuel lines up on the manifold side of the car - normally they run to the other, distributor side as thats where the mechanical fuel injection sits, but in the end I decided to keep to the normal fuel pipe routing, and ran two rubber hoses from the manifold fuel send and return, round the back of the engine, to the normal fuel pipe positions.

I have just about finished fitting the send and return pipes down the chassis, but I need 2 grommets to pass the fuel pipe through the floor under the fuel tank, and without these I couldn't complete the work. Once these are fitted I'll finish clipping the fuel pipe to the chassis rails, and complete the job.

Before anyone asks I have flared the ends of the copper pipe so that a good reliable seal is made to the rubber.

I need to wire up the pumps, but thats a job for when I finish the wiring

Sunday, 12 April 2015

TR5 Interior

This may not look like much, but its taken 3 days work to get to this point.

The interior is now finished (although I have to bolt the seats in, and fit the door cards).

The carpets are correctly secured with the snap rings too - what a pain of a job!

The H frame on the transmission tunnel was fun too - a very tight fit at present. The gear knob is not original (although I have the original one) as I have fited an overdrive logic controller - actuated by the small black button on the right hand side of the gearknob. so no changing up into a gear with overdrive already selected !

The next item to have attention was the grill, you cannot even get repro ones, and although the grill was in good condition the anodising had worn through in many places. I looked at having it re-anodised, but the consensus was that stripping and polishing would probably damage the alloy, so I have taken a different approach.

After a good clean, I have sprayed it with acid etch primer, then a coat of white primer, follwed by a chrome paint. When this has dried, I shall mask off and apply the matt black - it will be interesting to see how this comes out - and if its no good I can always strip it off again and try re-anodising.

Grey primer

and now chrome paint applied - front

and back

The pictures actually don't do it justice, it looks far shiney in reality

So all thats left now is:-

fit the grill

fit door cards

finish the elctrics

fit fuel pump and lines

fit the hood

fit an exhaust

and then find all the niggles !

By the way got another nice part got the Sprint, a nice new old stock gearbox mount

The interior is now finished (although I have to bolt the seats in, and fit the door cards).

The carpets are correctly secured with the snap rings too - what a pain of a job!

The H frame on the transmission tunnel was fun too - a very tight fit at present. The gear knob is not original (although I have the original one) as I have fited an overdrive logic controller - actuated by the small black button on the right hand side of the gearknob. so no changing up into a gear with overdrive already selected !

The next item to have attention was the grill, you cannot even get repro ones, and although the grill was in good condition the anodising had worn through in many places. I looked at having it re-anodised, but the consensus was that stripping and polishing would probably damage the alloy, so I have taken a different approach.

After a good clean, I have sprayed it with acid etch primer, then a coat of white primer, follwed by a chrome paint. When this has dried, I shall mask off and apply the matt black - it will be interesting to see how this comes out - and if its no good I can always strip it off again and try re-anodising.

Grey primer

and now chrome paint applied - front

and back

The pictures actually don't do it justice, it looks far shiney in reality

So all thats left now is:-

fit the grill

fit door cards

finish the elctrics

fit fuel pump and lines

fit the hood

fit an exhaust

and then find all the niggles !

By the way got another nice part got the Sprint, a nice new old stock gearbox mount

Sunday, 29 March 2015

More TR5 Work

I had a good session on the 5 this weekend.

Firstly I bled the brake system and the car finally has a working brake system, although I still need to adjust the rerar brakes and handbrake cables, but thats waiting on obtaining the correct clevis pins for the handbrake cables.

Next was seat work, I had purchased some 3mm steel rod, so a happy hour or two was spent bending it into the shapes needed to replaced the damaged "wing" frames on the seats.

That done I strted to affix the foams to the seats

and then fit the seat covers

which have to be done in stages, glueing the centre of the cover into the foams, with a weight on top to make sure it fits the lower area.

This was repeated with the top covers too, until I ended up with this

I then needed to tension the covers by stretching the cover over the base, and fit the seat tilt release

That done I had two complete finished seats.

With a little bit of time to spare I got round to fitting the rear wheel arch trims, and the B post trim.

Carpets next, but I put the seats in the car just to see what they looked like

I must finish fuel pipes and electrics next before I do much more trim work

Firstly I bled the brake system and the car finally has a working brake system, although I still need to adjust the rerar brakes and handbrake cables, but thats waiting on obtaining the correct clevis pins for the handbrake cables.

Next was seat work, I had purchased some 3mm steel rod, so a happy hour or two was spent bending it into the shapes needed to replaced the damaged "wing" frames on the seats.

That done I strted to affix the foams to the seats

and then fit the seat covers

which have to be done in stages, glueing the centre of the cover into the foams, with a weight on top to make sure it fits the lower area.

This was repeated with the top covers too, until I ended up with this

I then needed to tension the covers by stretching the cover over the base, and fit the seat tilt release

That done I had two complete finished seats.

With a little bit of time to spare I got round to fitting the rear wheel arch trims, and the B post trim.

Carpets next, but I put the seats in the car just to see what they looked like

I must finish fuel pipes and electrics next before I do much more trim work

Monday, 23 March 2015

Sprint Parts

I didn't quite make it to Norway today, for some reason my visit got postponed, however some more nice parts arrived for the Sprint, firstly an airbox - designed for webbers, but I don't see why it won't work for Jenvey bodies - just need to cut the intakes, and make provision for an intake pipe.

and head studs with UNC thread for the block end, and UNF for the nuts which allows for more accurate torquing of the head

and head studs with UNC thread for the block end, and UNF for the nuts which allows for more accurate torquing of the head

Sunday, 22 March 2015

I have a clutch

Well at least the TR5 does, first job of the day was to check all the pipe connections in the clutch system and bleed the system. I had the usual issues with big gear box clutches of not being able to pump the fluid through (on new systems), but I have recently purchesed a hand operated brake vacuum pump, which you attach to the bleed nipple and it sucks fluid through. That done I have a working clutch with a bite point abouit 3/4 way, I am happy with this, as the 5 has a tilton hydraulic release mechanism fitted (no cross shaft etc), and as the plate wears, the release bearing is pushed away from the flywheel, so making the pedal actuate the clutch with less travel, so its good it starts near the bottom of the pedal travel. If it was near the top, it would soon be into clutch slip as it wore as the hydraulic mechanism would not be able to retract far enough with your foot off the pedal.

Now that I have a working clutch I can fit the tunnel cover, but first the tunnel seals want replacing (I prefer the old cardboard tunnels to the plastic repro's as the fit isn't always so good, and I had a really good condition cardboard tunnel cover)

And now tunnel fitted, a bit of a pig of a job with the new seals, it'll be easier next time !

And thats it another 5 hours work !

I'm off to Norway tomorrow for a week's work with Top Gear, so more in 2 weeks time

Now that I have a working clutch I can fit the tunnel cover, but first the tunnel seals want replacing (I prefer the old cardboard tunnels to the plastic repro's as the fit isn't always so good, and I had a really good condition cardboard tunnel cover)

And now tunnel fitted, a bit of a pig of a job with the new seals, it'll be easier next time !

And thats it another 5 hours work !

I'm off to Norway tomorrow for a week's work with Top Gear, so more in 2 weeks time

Saturday, 21 March 2015

TR5 seats and brakes

Another day on the 5, but nothing quite finished. Brake and clutch pipes are finished now EXCEPT for the rear trailing arm pipes, The kunnifer pipe work is finished, but I had forgot that the braided flexi pipes always come with nuts that are too deep to allow the pipe unions to compres down on the trailing arms, so two standard thin nuts need ordering to complete this

Now to the seats, the first one went fine and I got the membrane and rear cushion support installed

But when working on the second seat I found that parts of the rear cushion support had rusted through

So I need to find some 3mm rod to bend to shape to replace the cushion supports that are damaged. I could have completed the first seat but decided to leave it bare so that I can dimension the wires from this, so nothing finished today

Now to the seats, the first one went fine and I got the membrane and rear cushion support installed

But when working on the second seat I found that parts of the rear cushion support had rusted through

So I need to find some 3mm rod to bend to shape to replace the cushion supports that are damaged. I could have completed the first seat but decided to leave it bare so that I can dimension the wires from this, so nothing finished today

Tuesday, 17 March 2015

TR5 Progress

I haven't managed to do as much on the 5 as I had hoped because of family commitments and the CT Dinner, which left me wrecked last Sunday.

Anyway what I have done is this

Got the accelerator pedal fitted

Door locks in place

Door internals finished, all locks and catches work as they should

I have started to make and fit up the clutch and brake lines - I have made these up with kunifer as its more durable than copper and doesn't work harden in the same way. Also it looks more like the original steel pipes.

Finally I collected the seat frames up, after being blasted and powder coated

I hope to get more done this weekend

Anyway what I have done is this

Got the accelerator pedal fitted

Door locks in place

Door internals finished, all locks and catches work as they should

I have started to make and fit up the clutch and brake lines - I have made these up with kunifer as its more durable than copper and doesn't work harden in the same way. Also it looks more like the original steel pipes.

Finally I collected the seat frames up, after being blasted and powder coated

I hope to get more done this weekend

Subscribe to:

Comments (Atom)

.JPG)

.JPG)