Domestic duties over I finally got a chance to take the Sprint for a drive today and get on with letting auto-tune correct the fuel map.

The first run out gave me this, I was still having issues with it being so rich that it bogged down at WOT, but after this run I then manually reduced the fuel table figures of cells that hadn't been auto-tuned and were adjacent to "tuned cells" where there was a large fueling jump.

This was a lot better and my second run out produced this - still some red cells with large disparities to adjacent ones, but much better and it is now hard to make it bog down

While its getting better to drive - and there's certainly more power there than in its previous carburettor equipped mode, it is getting difficult to explore the outer reaches of the fuel map without risk to my license ! I can see a rolling road session being booked soon.

Was the EFI conversion worth it? - you bet, it starts better, hot or cold, and has far more get up and go - I don't know about the fuel economy yet, but that's got to be better

Monday, 30 May 2016

Saturday, 21 May 2016

Airbox finished

Today was spent tidying up the wiring and fixing cable ties to any loose wires, and replacing the dash.

I need to build a little amplifier for the Microsquirt Tacho drive, as although I have a Smiths RVC type tacho, the output is insufficient to drive it, - that's a little project to be done at work.

I then got on with finishing the air box and filter, I had purchased this K&N cone type filter and fittings, so it was time to fit it.

Filter in place - should get lots of cold air here, with the input just behind the grill. This is why I relocated the battery.

I then needed to fit an input to the airbox, I had intended to fit this between cylinders 2 and 3 but realised if I did this that I wouldn't be able to get my hand down to the dipstick, so I had to move it along a little, here's the input fibre glassed in place, I also glassed in the IAT bung

And now all fitted

with its lid in place.

What else to do but drive the car and try and get autotune to correct the fueling, because of heavy traffic I could only get about one third of the fuel cells corrected, and it was certainly running very rich, too much accelerator (and hence extra enrichment) and the car bogged down, and the AFR went too rich and off the scale, but its progress, I managed about 30 miles in it today, but I really need to take it for a good run with no cars about to finish the other cells !

The only other job is to either replace the lift pump or at least mount it on rubber bobbins as its a little noisy !

I need to build a little amplifier for the Microsquirt Tacho drive, as although I have a Smiths RVC type tacho, the output is insufficient to drive it, - that's a little project to be done at work.

I then got on with finishing the air box and filter, I had purchased this K&N cone type filter and fittings, so it was time to fit it.

Filter in place - should get lots of cold air here, with the input just behind the grill. This is why I relocated the battery.

I then needed to fit an input to the airbox, I had intended to fit this between cylinders 2 and 3 but realised if I did this that I wouldn't be able to get my hand down to the dipstick, so I had to move it along a little, here's the input fibre glassed in place, I also glassed in the IAT bung

And now all fitted

with its lid in place.

What else to do but drive the car and try and get autotune to correct the fueling, because of heavy traffic I could only get about one third of the fuel cells corrected, and it was certainly running very rich, too much accelerator (and hence extra enrichment) and the car bogged down, and the AFR went too rich and off the scale, but its progress, I managed about 30 miles in it today, but I really need to take it for a good run with no cars about to finish the other cells !

The only other job is to either replace the lift pump or at least mount it on rubber bobbins as its a little noisy !

Tuesday, 17 May 2016

Running with EFI

I have done a little more work on the Sprint in the past 2 nights.

First job was to get the AFR reading on Tune to reflect the dash gauge reading - I had selected Techedge as the controller, but forgotten to burn the settings into Microsquirt, which resolved that issue

The MAP sensor wasn't giving a reading, I had wired it as a standard GM device, but upon checking found that 5v and sensor wires needed swapping over, so I corrected that, and by "sucking" on the tube could then get Tune to show a changing reading. I then used the data sheet for the sensor to put the calibration points into Tune - that done I had a reading at rest of 96kpa - close enough to the desired 100 kpa at sea level.

I then fitted the vacuum tubes from the manifold to the MAP sensor and the fuel pressure regulator.

That done I started the engine and it was a lot, lot better, as soon as it was at temperature I used the autotune to correct the low revs fueling, which was all set too high. RESULT ! in fact it was running well enough to take it for a very short drive, which let me autotune more fuel cells.

Tickover is now stable at 800 rpm, and it pulls off without hesitation

I didn't drive far as the dash is still loose and the airbox and filter are not complete, but it works well.

I suspect the cold start needs some attention but I will leave it for now until I have proper air filtration.

The filter parts will be with me tomorrow, but I think if all goes well it will be back on the road this weekend.

First job was to get the AFR reading on Tune to reflect the dash gauge reading - I had selected Techedge as the controller, but forgotten to burn the settings into Microsquirt, which resolved that issue

The MAP sensor wasn't giving a reading, I had wired it as a standard GM device, but upon checking found that 5v and sensor wires needed swapping over, so I corrected that, and by "sucking" on the tube could then get Tune to show a changing reading. I then used the data sheet for the sensor to put the calibration points into Tune - that done I had a reading at rest of 96kpa - close enough to the desired 100 kpa at sea level.

I then fitted the vacuum tubes from the manifold to the MAP sensor and the fuel pressure regulator.

That done I started the engine and it was a lot, lot better, as soon as it was at temperature I used the autotune to correct the low revs fueling, which was all set too high. RESULT ! in fact it was running well enough to take it for a very short drive, which let me autotune more fuel cells.

Tickover is now stable at 800 rpm, and it pulls off without hesitation

I didn't drive far as the dash is still loose and the airbox and filter are not complete, but it works well.

I suspect the cold start needs some attention but I will leave it for now until I have proper air filtration.

The filter parts will be with me tomorrow, but I think if all goes well it will be back on the road this weekend.

Sunday, 15 May 2016

Its alive !

I started today by removing the old fuel pipe, and then running the high pressure send and return lines - another nice day lying flat on my back under a car.

So here's the fuel lines where they enter the boot

and a view of them going to the front of the car

All plumbed in to the swirl pot

and connected to the fuel rail

and pressure regulator.

I then powered up the 2 fuel pumps, and could hear the high pressure one start, with bubbles and gurgling noises coming from the swirl pot as the air was expelled. No fuel leaks though!

The lambda sensor was then fitted and connected to its controller, its a fair way back down the exhaust, but this doesn't matter as it has its own heater, and the "self tune mode" of megasquirt is supposed to allow for the sensor delays due to distance.

I then was going to start the car, but I notice when the fuel pump relay "timed out" at the end of 2 seconds, the controller rebooted and started the timing cycle again. I traced this back to a back emf pulse from the ignition circuits, microsquirt wiring diagrams show the ignition system powered off the fuel relay, whereas megasquirt has a separate relay. So I then fitted an additional relay in my fuse/relay box, fed with a separate power feed, but still ignition switched - the difference now being that its ignition switch controlled, and not by the microsquirt, and all was well.

It did start first time

and I have it running reasonably well at a highish tickover speed. It gets a bit lumpy at tickover - its running too rich as shown by the lambda sensor, but you can see the spark timing vary, and if it slows too much the extra advance I have put in the table at slow rpms stops it stalling.

Microsquirt is also showing an incorrect lambda value, compared to the dash meter, so I need to check I have used the correct table in microsquirt - I presume the one currently used is incorrect.

However water temp, air temp and rpm, and throttle position all show correctly on Megatune, and the ignition timing also seems to vary as it should, so all good with these

I have a few jobs to finish before I try it on the road, I need to finish the airbox and cold air intake, tidy up cables, see if I can get the tacho drive to work, and fit the vacuum tubes to the map sensor and efi fuel regulator - I have it running in Alpha N mode at present, but would like to use MAP as well

So here's the fuel lines where they enter the boot

and a view of them going to the front of the car

All plumbed in to the swirl pot

and connected to the fuel rail

and pressure regulator.

I then powered up the 2 fuel pumps, and could hear the high pressure one start, with bubbles and gurgling noises coming from the swirl pot as the air was expelled. No fuel leaks though!

The lambda sensor was then fitted and connected to its controller, its a fair way back down the exhaust, but this doesn't matter as it has its own heater, and the "self tune mode" of megasquirt is supposed to allow for the sensor delays due to distance.

I then was going to start the car, but I notice when the fuel pump relay "timed out" at the end of 2 seconds, the controller rebooted and started the timing cycle again. I traced this back to a back emf pulse from the ignition circuits, microsquirt wiring diagrams show the ignition system powered off the fuel relay, whereas megasquirt has a separate relay. So I then fitted an additional relay in my fuse/relay box, fed with a separate power feed, but still ignition switched - the difference now being that its ignition switch controlled, and not by the microsquirt, and all was well.

It did start first time

and I have it running reasonably well at a highish tickover speed. It gets a bit lumpy at tickover - its running too rich as shown by the lambda sensor, but you can see the spark timing vary, and if it slows too much the extra advance I have put in the table at slow rpms stops it stalling.

Microsquirt is also showing an incorrect lambda value, compared to the dash meter, so I need to check I have used the correct table in microsquirt - I presume the one currently used is incorrect.

However water temp, air temp and rpm, and throttle position all show correctly on Megatune, and the ignition timing also seems to vary as it should, so all good with these

I have a few jobs to finish before I try it on the road, I need to finish the airbox and cold air intake, tidy up cables, see if I can get the tacho drive to work, and fit the vacuum tubes to the map sensor and efi fuel regulator - I have it running in Alpha N mode at present, but would like to use MAP as well

Saturday, 14 May 2016

More EFI work

After having to work last weekend, I am hoping to get the Sprint running on EFI this weekend ...we shall see.

So first job today was to relocate the battery, and run the battery cables down the inner sill, using rubber lined P clips to secure the cables

I am intending to fit a larger battery in due course, and as you can see with the spare wheel back in place there is lots of room

With power restored to the car, I got on with the fuel system, first fitting the swirl pot and integral high pressure pump, and inline high pressure filter - all wiring has been loomed up as usual

lift pump and filter

and the swirl pot tank return, I have used a Stag fuel filler hose in place of the original Dolomite one, which has a breather connection for the tank which I have used for the fuel return from the swirl pot.

Out of interest I powered up the lift pump, and it filled the swirl pot without leaks, and I could hear the return into the tank.

With luck I am hoping to fit the high pressure fuel lines tomorrow

So first job today was to relocate the battery, and run the battery cables down the inner sill, using rubber lined P clips to secure the cables

I am intending to fit a larger battery in due course, and as you can see with the spare wheel back in place there is lots of room

With power restored to the car, I got on with the fuel system, first fitting the swirl pot and integral high pressure pump, and inline high pressure filter - all wiring has been loomed up as usual

lift pump and filter

and the swirl pot tank return, I have used a Stag fuel filler hose in place of the original Dolomite one, which has a breather connection for the tank which I have used for the fuel return from the swirl pot.

Out of interest I powered up the lift pump, and it filled the swirl pot without leaks, and I could hear the return into the tank.

With luck I am hoping to fit the high pressure fuel lines tomorrow

Sunday, 1 May 2016

Sprint EFI work

Not complete yet but good progress made.

I collected the inlet manifold on Friday, which has had a boss welded on for the Coolant Sensor

Next job was to strip out the old carbs and ancilliary items - as its a slant4 there's lots of room when everything has gone.

I have also removed the battery as I want to relocate this to the boot, so I can fit a larger battery and have room for the airbox.

So time to fit the new manifold and refit heater hoses, with a new stainless steel heater pipe - the old one was somewhat rusty

next fit the injector bodies, so I can make up the wiring loom - I have run separate looms for sensors, and the injectors to reduce interference to the sensor circuits

map sensor with loom

injectors wired, with plug for IAT sensor visible

The throttle is also connected and the fuel pressure regulator

I trial fitted the new batter cables to a loose battery, just to see if everything works as it should - all the wing wiring mods were correct, and Megasquirt now shows coolant and air temp correctly, and I could calibrate the throttle position sensor. I am not sure about the MAF sensor though - it needs the wiring or perhaps the pin outs on the connector checking as there seems to be no change in the readings when you "suck" on the input.

Apart from that I need to fit the battery cables, fuel lines, swirl pot and the lambda sensor - so nearly there

I collected the inlet manifold on Friday, which has had a boss welded on for the Coolant Sensor

Next job was to strip out the old carbs and ancilliary items - as its a slant4 there's lots of room when everything has gone.

I have also removed the battery as I want to relocate this to the boot, so I can fit a larger battery and have room for the airbox.

So time to fit the new manifold and refit heater hoses, with a new stainless steel heater pipe - the old one was somewhat rusty

next fit the injector bodies, so I can make up the wiring loom - I have run separate looms for sensors, and the injectors to reduce interference to the sensor circuits

map sensor with loom

injectors wired, with plug for IAT sensor visible

coolant sensor and wiring just visible bellow the thermostat housing

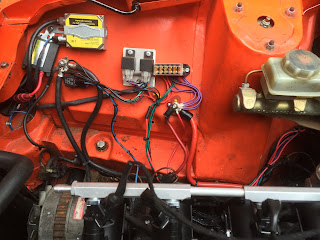

I have now sorted out the inner wing wiring, the loose fuses have gone to be replaced with a fuse box, and a new earth strap was made and fitted, and also on the body terminal you can see the negative battery wire, which will go to the boot with the positive cable, which is now fitted to an insulated stud, which has the headlamp and fan relays connected to it with the starter motor feed - I now have to run the 2 battery wires to the boot, but I shall do that when I fit the fuel lines

Trial fit of the airbox, air horns and the IAT sensor - this needs the boss "glassing" into place, when I fit the air intake to the airbox, I am intending to fit a large cone filter behind the grill where the battery normally fits and feed this to the middle of the airbox, coming up into the airbox from underneath, between cylinders 2 and 3 - this will also let me fit a MAF in the airfeed, if I want

I trial fitted the new batter cables to a loose battery, just to see if everything works as it should - all the wing wiring mods were correct, and Megasquirt now shows coolant and air temp correctly, and I could calibrate the throttle position sensor. I am not sure about the MAF sensor though - it needs the wiring or perhaps the pin outs on the connector checking as there seems to be no change in the readings when you "suck" on the input.

Apart from that I need to fit the battery cables, fuel lines, swirl pot and the lambda sensor - so nearly there

Subscribe to:

Comments (Atom)